Have you ever looked at a column, or the foundations of a bridge and wondered how the engineers that built it could be sure the weight would hold?

It’s not magic or guesswork. With an understanding of how different forces affect structures and materials, you’ll be able to safely plan your next project without worrying whether or not it will collapse.

What is compressive strength?

Throughout the construction of a project, you’ll be using different materials for different tasks. Sandstone, brick, concrete, steel... But when you’re deciding what material to use it's important you understand they each possess different qualities. One of which is compressive strength.

All materials can withstand a certain amount of compression (a force which tries to squash things together). Compressive strength refers to the amount of pressure that a material can withstand before it begins to fail at a molecular level. I.e how much force a material can resist before its size is reduced and the material cracks or breaks.

Whether you’re working on tunnel systems, bridges, or residential homes, it’s vital that you have an understanding of compressive strength and how it impacts the structure you are building. That way you can avoid potential disasters (not mentioning any European landmarks which may or may not have been built on sand and shells).

Why is it needed in engineering?

Over time, buildings and other structures are subject to a number of internal and external loads that try to push them into the ground or against more resistant materials. Because of this, you need to know the strength of the materials you are planning to use and how resistant they are.

These loads are typically broken down into three main categories:

Dead loads

This is the weight of the structure itself. The bricks, pipework, wood etc.

Living loads

Think about the people visiting, items or vehicles that pass through or over the structure, and anything that isn’t fixed and has been designed to move.

Environmental loads

Naturally occurring events such as weather. These can be broken down further into a whole series of subcategories but typical considerations include wind, rain, snow, and even earthquakes.

If you’d like to learn more about each of these subcategories, check out this blog by constrofacilitaor.com

How to measure compressive strength

All materials can be tested for compressive strength as long as it’s done correctly and in a rigorous and scientific manner. Pieces of test materials are placed into a machine, in the shape of a cube, prism, or cylinder. The machine gradually applies more pressure until the test material fails and cracks.

Compressive strength is then calculated using the below formula and typically presented using PSI (Pounds Per Square Inch).

F = P/A

F= The compressive strength

P= Maximum load before failure (normally measured in Newtons or Pounds)

A= The cross-section of the area that is resisting the load

It’s unlikely that you’ll ever need to test the strength of a material yourself, but if you’d like to find out more, then we suggest checking out this article by britannica.com.

Characteristic compressive strength

Another term you may come across when discussing the strength of different construction materials is Characteristic Compressive Strength.

Think of this like a grading system. It’s a rating assigned to materials that have been tested (as mentioned above) and where a maximum of 5% of the test pieces failed. I.e if you were to test 100 pieces of concrete and 95 of them could resist 5000 PSI before failing, the characteristic compressive strength would be 5000 PSI.

Other forces to consider

Unfortunately, compression isn’t the only thing that will impact the structures you work on. Different types of ‘loads’ (mentioned above) will test the materials you use in a variety of ways. Over time, they’ll be compressed, pulled, twisted, and pushed. For this reason, you should also be aware of the following forces and how they behave.

Tension: Stretches and pulls in opposite directions

Torsion: Causes twisting

Shear: Pushes in opposite directions simultaneously

Bending: Stretches and squashes at the same time

Strengths of common materials

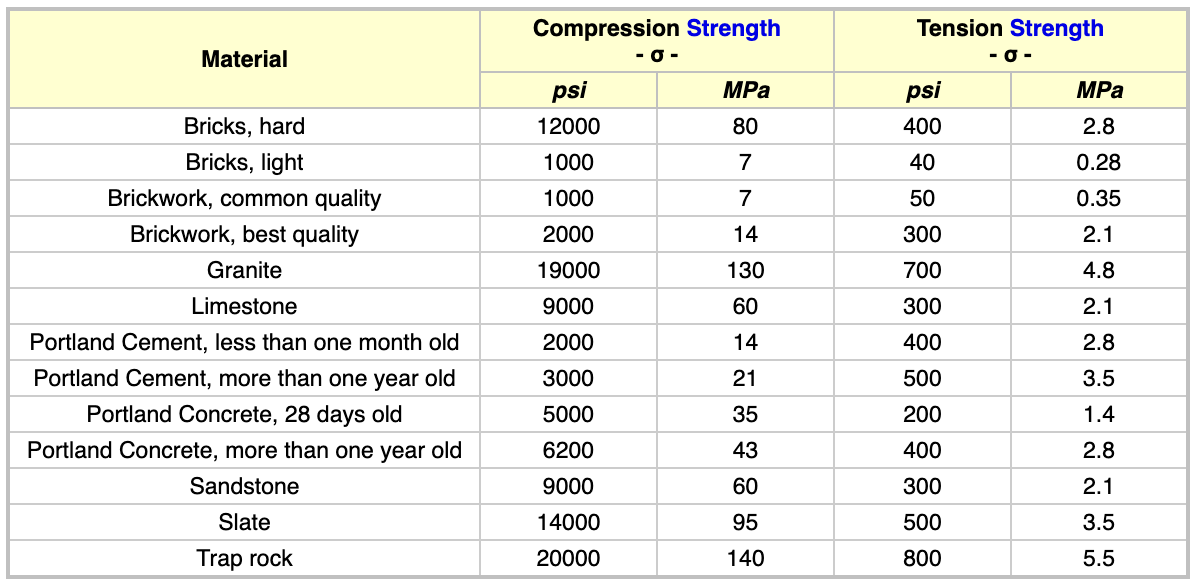

It’s worth noting that the exact strength of different materials might vary slightly depending on the quality. When deciding what material to use, you’ll need to consider the variations of quality available as well as the product itself.

Check out the table below for the approximate strength of different materials.

Source: https://www.engineeringtoolbox.com/compression-tension-strength-d_1352.html

The compressive strength of concrete

When it comes to construction, concrete is widely considered to be the most important material to test for compressive strength.

The first reason for this is that while many materials possess resistance to a number of forces, concrete only has a high resistance to compression. For example, the compressive strength of steel is equal to its tensile strength. But, concrete is considerably less resistant to tension than it is compression. It is for this reason that concrete is often reinforced with rebar.

The second reason is that the compressive strength of concrete will vary greatly depending on the method used to cure it. If cured with the optimal amount of moisture then the concrete will achieve the required compression strength faster; its final strength will also be higher than it would have been if it was left to cure in open air.

Conclusion

All materials have varying amounts of compressive resistance they can take before failing.

With an understanding of compressive strength (and related forces) you can safely plan construction projects without worrying about whether or not they are structurally sound.

Bear in mind that different materials have different strengths depending on their quality. The exact structure you are building and forces that are likely to impact it will determine how resistant the material used will need to be.

Thanks for reading! If you enjoyed this article and would like to learn more about the construction industry and/or Aphex, you can view all of our blogs and articles here.